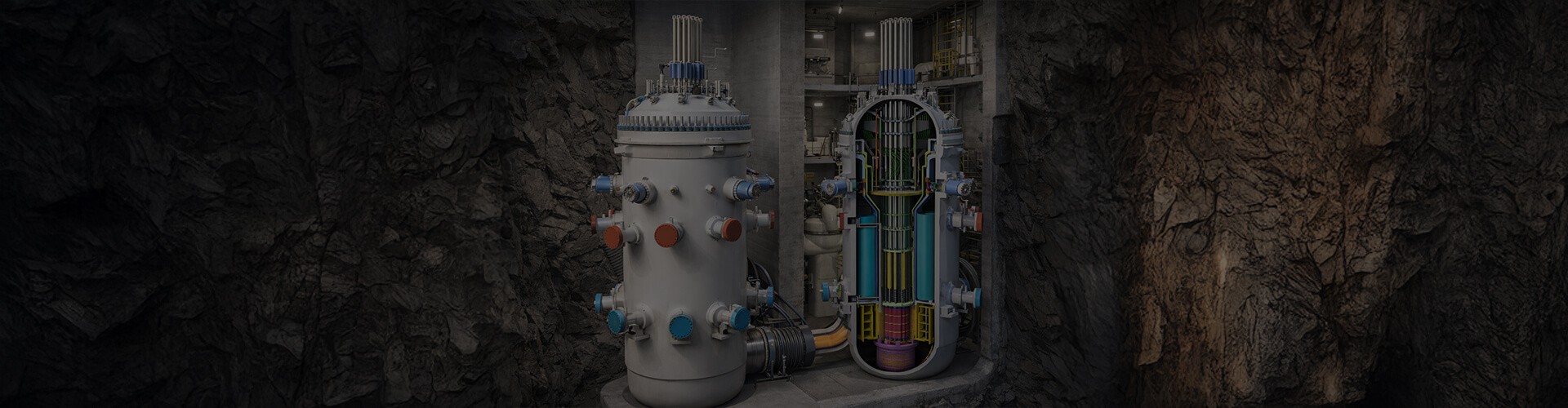

Small Modular Fusion Reactors represent the next frontier in clean energy, replicating the sun's power generation mechanism in compact, factory-built units producing 50-300 MW. Unlike conventional fusion megaprojects, SMFRs leverage advanced engineering, high-temperature superconducting magnets, and innovative confinement geometries to achieve viable economics at reduced scale. Leading approaches include tokamak configurations with compact, high-field designs reaching magnetic fields of 12-20 Tesla.

The name - tokamak, comes from a Russian acronym meaning "toroidal chamber with magnetic coils." Spherical tokamaks offering improved plasma stability and confinement efficiency, and stellarator designs eliminating plasma current disruptions through optimized magnetic field geometry. Inertial confinement fusion using high-energy lasers or particle beams compresses fuel targets to achieve ignition conditions. Alternative concepts include field-reversed configurations (FRC), which confine plasma without toroidal magnetic fields, and magnetized target fusion combining magnetic and inertial confinement principles. The fusion reaction fuses deuterium and tritium nuclei at temperatures exceeding 100 million degrees Celsius, releasing enormous energy as high-energy neutrons. These neutrons interact with lithium-containing breeding blankets, generating tritium fuel while producing thermal energy for electricity generation. SMFRs offer inherent safety advantages including no chain reactions, limited fuel inventory, and passive decay heat removal. The absence of long-lived radioactive waste (activated materials decay to background levels within 100 years) and impossibility of meltdown or weapons proliferation make fusion politically and socially acceptable. Manufacturing in controlled factory environments ensures quality control and reduces construction time to 2-3 years.